Screen printing

Experience the revolution in the world of printing with our screen printing services! We offer unique solutions for all materials - from foils to glass. Our technology guarantees excellent colour fastness, long-lasting quality and cost-effectiveness. We adapt to your specific needs and guarantee that your projects will exceed expectations.

Letterpress

Discover the art of letterpress printing, an ancient printing technique that brings your projects to life with unparalleled quality. From interior labels to durable exterior applications, our technique from above brings detail, depth and durability. Explore how letterpress printing can enhance your materials and projects with unique properties and protective finishes.

Digital printing

Digital printing at BBH offers a fast, efficient solution for single and full colour projects on a variety of materials including paper, foil and anodised aluminium. Our technology allows for easy pre-press proofing, low costs, and offers a wide range of personalization options. We specialize in accurate, quality print results to suit your needs.

Anodizing

We offer a specialized anodizing service for your custom aluminum and aluminum alloy pieces, a process also known as anodizing. This electrolytic process creates a thin, anodically oxidized layer on the surface of aluminum items that not only improves aesthetic qualities, but also increases the product's resistance to mechanical damage and weathering. In addition to anodizing, we also offer the option of printing into the open oxidation layer using screen printing or digital printing, thus achieving high resistance to chemical influences, high temperatures, and ensuring colour fastness and lightfastness of the print. Once the oxidation layer has been sealed in a hot bath, the surface takes on a premium hardness, making our anodised aluminium labels ideal for any indoor or outdoor application, in a wide range of print colours.

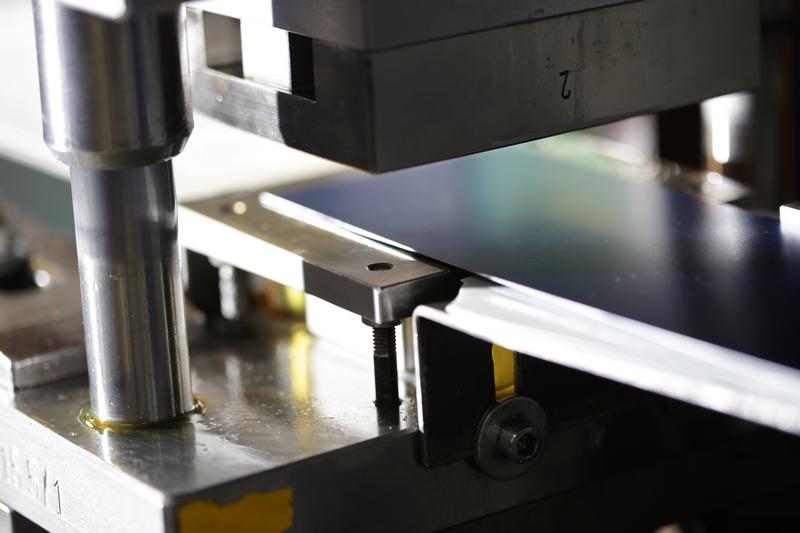

Pressing

We offer a comprehensive pressing service using eccentric presses with shear forces of 10 to 40 tonnes, enabling efficient processing of a wide range of materials - from plastics, through die-cut and aluminium sheets, to complex metal components for the automotive sector. Our specialization includes not only precision stamping, but also surface finishing, ensuring excellent quality and longevity of the final products. With attention to detail and an individual approach to each project, we guarantee that the results of our work fully meet the specific requirements and expectations of our clients.

Laser cutting

We use advanced laser cutting technology, which allows us to make precise laser cuts, both internal and peripheral cuts of plastics, even in the development of polycarbonate dials, which find their use especially in the automotive industry. Laser cutting has proven to be the ideal method for processing plastics and sheet material (except PVC) up to a maximum thickness of 2 mm, guaranteeing high precision and cleanliness of the cut. This technique brings efficiency and flexibility to our manufacturing processes, allowing us to complete projects with the high level of detail and precision required to meet the specific requirements of our Automotive clients.

Laser description

We offer a unique laser marking service that uses a special light beam to precisely remove a thin layer from the surface of the material. Our technology ensures high durability and legibility of the markings with a distinctive effect, without disturbing the material itself. With this method, we are able to achieve unrivalled accuracy and detail on a wide range of materials.

Graphic preparation

We offer our customers a complete processing of supplied graphic templates from text editing, through scanning and previewing, to production. We carry out complex graphic preparation for all types of technologies we offer.

UV varnishing

UV coating is a fast and cost-effective surface treatment technique with high gloss and durability. Suitable for paper, plastic, and metal, this method allows both full and partial applications, highlighting details such as logos or images with effects ranging from matt to glitter. We offer UV coating with excellent properties such as UV resistance, abrasion resistance, and the possibility of additional finishes for a unique look for your products.

Quality control and tool shop

Our company places great emphasis on the quality and precision of our products. We carry out thorough testing in our research department or externally, ensuring the highest standards are met under a variety of conditions. We use advanced optical measuring systems for 2D and 3D measurements, guaranteeing high form quality and accuracy. Our tool room offers customized stampings, with a wide range of shapes and sizes, according to customer specifications.